Announcement

Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!...Read more Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!

We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University....Read more We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University.

26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023....Read more 26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023.

Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!...Read more Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!

We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University....Read more We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University.

26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023....Read more 26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023.

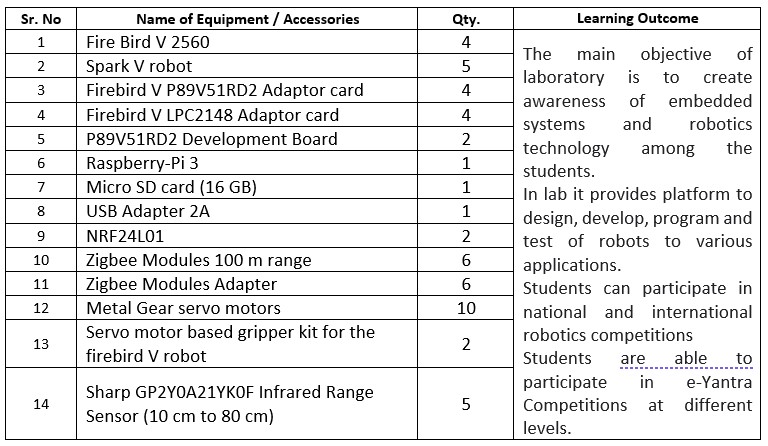

e-Yantra is a robotics outreach program funded by the Ministry of Education and hosted at IIT Bombay. The Robotics laboratory was established under e-Yantra initiative and funded by SSIP,-GOG and ICSII-Indus University.

The goal is to harness the talent of young engineers to solve problems using technology across a variety of domains such as: agriculture, manufacturing, defense, home, smart-city maintenance and service industries. Robotics Laboratory is an integral part of a department. When students programme physical robots, it becomes easier for them to understand the intricacies and capabilities of robots. They learn the skills needed to create precise and accurate instructions and have fun while learning valuable lessons.

E-Yantra Robotics Competition (eYRC): Engages students using Project Based Learning (PBL) to implement a solution to a real world problem. Winners get exciting prizes and an opportunity to get internship at e-Yantra, IIT Bombay.

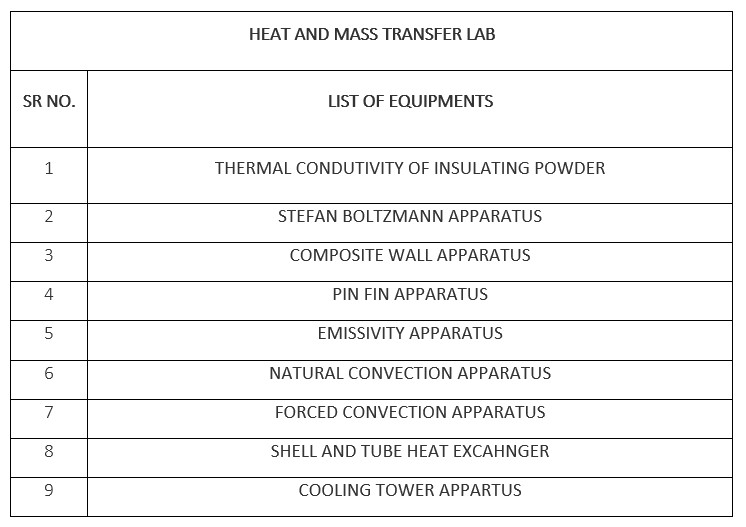

Heat and mass transfer lab helps the students to clearly understand the concepts and application in the field of heat and mass transfer which is one of the core subjects of Mechanical engineering.

The Heat and mass Transfer lab consists of various experimental setup and some Student fabricated projects. This lab course is primarily being offered to the III Year B.Tech Mechanical Engineering Students to make them understand the basic principles of heat and mass transfer i.e. conduction, convection, Radiation.Heat and Mass Transfer Lab consists of the following equipment

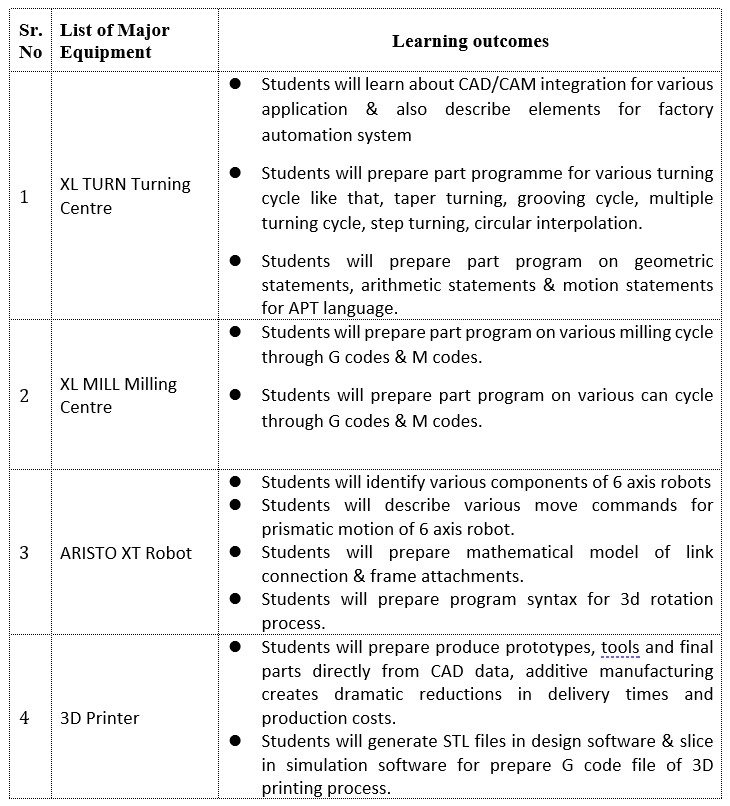

Computer Integrated Manufacturing (CIM) Laboratory provides knowledge and hands-on experiences on CNC machines and robot. The objectives of CIM Laboratory are to provide employability skills with the CNC programming and cutting tool path generation through CNC simulation software by using G-Codes and M-codes. Which are operated in simulation software “CNC TRAIN “under the Fanuc Controller. Students are preparing various Part programs for various lathe and Mill operations in this software and check the simulation before the running of machines. CNC Lathe part programming for Turning, Facing, Chamfering, Grooving, Step turning, Taper turning, Circular interpolation, Combination of few operations followed by CNC Mill Part programming for Point to point motions, Line motions, Circular interpolation, Contour motion, Pocket milling- circular, rectangular, Mirror commands in addition part programming using Canned Cycles for Drilling, Peck drilling, Boring, Tapping, Turning.Cim lab also featured with 6 Axis Robot and 3D Printer to facilitate efficient design process and demonstrate axis configurations for different kinematics. CIM Lab also provides R&D facility to students for their Projects.

Metrology, the science of measurement, helps manufacturers to attain the proper fit and finish for their products. It embraces both experimental and theoretical measurements and determinations at any level of uncertainty in any field of science and technology. Measurement and Instrumentation techniques are among the most important tools used by Engineers and Scientists. Experimental methods and the proper use of various types of measurement systems provide the basis for the design, evaluation, and control of many engineering components and systems. An engineering test is often the only substitute for analysis of new designs in cases where a purely analytical approach would be difficult, inaccurate, or impossible. Even in cases where analysis provides a starting point for evaluation, standard engineering practice includes validation testing – e.g., using measurement and instrumentation techniques – to confirm engineering analysis results. Thus, a good working knowledge of this area of study is critical to effective engineering implementation. Metrology and Instrumentation Lab plays a crucial role for a student who wants to pursue his career in industrial engineering and shop floor control. MT& I lab’s list of experiments is chosen in such a way to familiarize our B. Tech students in various kinds of measuring tools/instruments, measuring techniques, measurement methods, calibration procedures, SQC procedures. The students learn the measurement procedure in basic measuring instruments such as Vernier caliper, micrometer, slip gauge, Vernier height gauge, plug gauge, bore gauge, thread micrometer, gear tooth vernier, dial gauge, GO-NO gauges, Surface roughness tester, etc. The calibration exercise makes them find the standard error involved in the measuring instrument using a set of slip gauges.

The strength of the material is the body of knowledge that deals with the relation between internal forces, deformations and external loads, etc. This laboratory provides the basic knowledge of the strength of materials and here, the students can perform different tests on different materials. The laboratory is equipped with various equipment, which enable students to comprehend properties of different materials such as hardness, elasticity, ductility, different types of stresses etc.

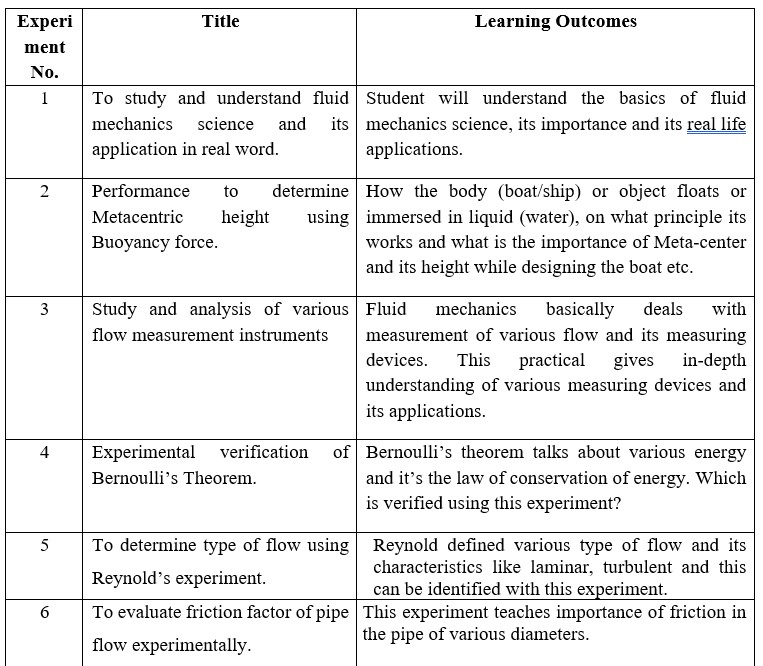

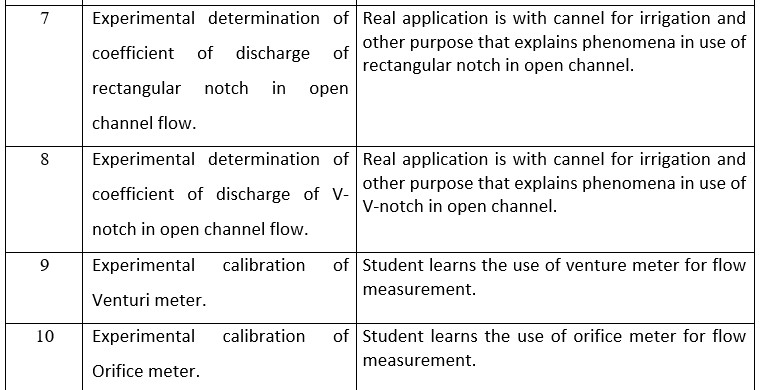

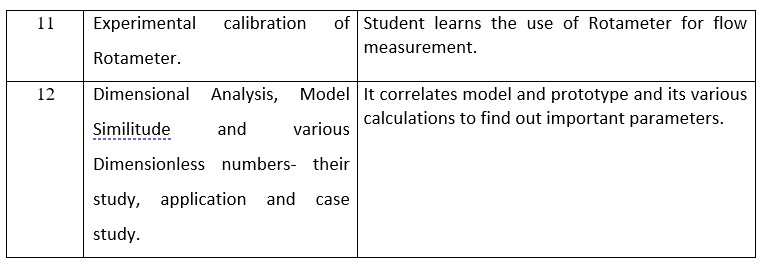

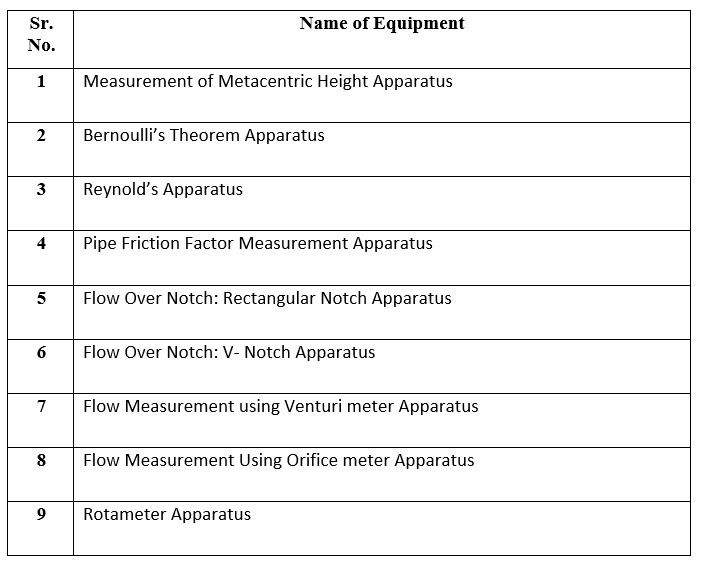

Fluid Mechanics is of vital importance in energy conversion systems i.e. mainly deals with hydro power, in process industry (paper, metals, polymers etc.) and for transports (airplanes, ships etc.). This lab is run in conjunction with the theory courses offered by various departments namely Mechanical, Civil and Automobile Engineering. It is an introductory course where flow behavior, fluid forces and analysis tools are introduced. The goals of the experiments include determination of forces generated when fluid flow takes place over a solid object, applications of the control volume approach, ddemonstration of the momentum and energy equations, viscosity measurement and engineering correlations. Intricate flow phenomena such as separations and transition to turbulence are demonstrated. Experimental setups such as flow through a tube, flow over a flat plate, wind tunnel, are made available to the students. The lab experiments utilize U-tube manometer and multi-tube manometer etc. The lab runs closely with the lectures in such a way that experiments support the text covered in the class room.

The objective of EME laboratory is to make every student aware for practical knowledge related to important equipment and concepts such as understand the phenomenon of evaporation, different configuration of steam generator, different boiler mountings, different IC Engine models like 2-stroke: 4-stroke engines, different types of pumps, compressor, Refrigeration & Air compressor, motion and power transmission, applications of couplings, clutch and brake etc. This helps the students to fill the gap between theoretical and practical knowledge of respective subject.

Brief about Lab:

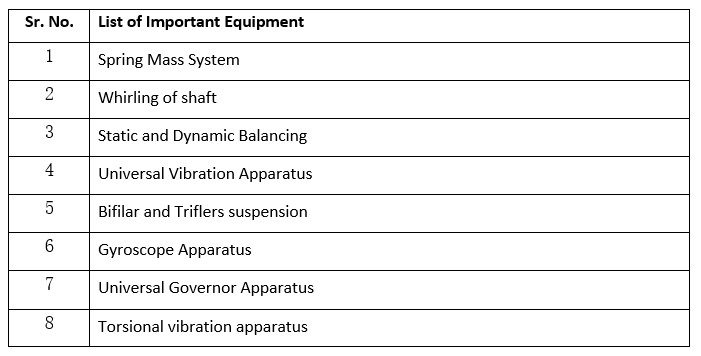

Dynamics of Machine lab imparts practical knowledge on design and analysis of mechanisms in the machine tools and automobiles. In Dynamics of Machine Lab, the students are doing the experiments related to their theory subjects like Dynamics of Machine and Mechanical Vibration.

Various experiments with governors, gyroscopes, balancing machines and universal vibration facilities are available to understand machine dynamics. Watt governor, Porter governor, Proell Governor, Hartnell governor are installed in lab to study their performance, stability and sensitivity. Students can study the gyroscopic effect on aero plane, ship and automobiles by conducting experiment on motorized gyroscope. The students can study about the methods of reducing the unbalance forces on static and dynamics balancing machine. Thus, Dynamics of machine lab is developed in such a way that students can understand the basic concept of machines in a logical and innovative manner.

Outcomes:

Spring Mass

The Computer Aided Design (CAD) Laboratory of mechanical engineering department is well-equipped with 28 individual workstations. High-end terminal supported by latest hardware and software. CAD laboratory is equipped with software like Auto CAD, Inventor, ANSYS, MATLAB etc. and advanced mechanical engineering software are procured for making the students globally competitive and industry ready. At CAD lab, students get professional training on 2D drafting & 3D modeling of industrial parts using the latest version of software. Student will learn computer aided design layout and 3D solid modelling definition. Students will also gain the knowledge of design and drafting needed for mechanical engineering discipline.

Mechanical Engineering Workshop is a place where students acquire knowledge on the operation of various processes involved in manufacturing and production. The Workshop Practice course makes students competent in handling practical work in engineering environment. The mechanical engineering field requires an understanding of various manufacturing methods and processes by means of which one can convert the idea into physical products. To achieve the basic objective and to bridge the gap between Theory and Practice, a Department of Mechanical Engineering is equipped with various Machines, Tools and Equipment in Mechanical Workshop.

The Mechanical Workshop is divided into two groups as follows:

Basic Workshop activities are helpful for molding the skill and quality of the students to design and fabricate something by hand. The laboratory work is having hands on practice by using various tools and Equipment on different materials like; Wood, Metal, pipes etc. The basic workshop contains 6 different shops like; Fitting, Carpentry, Tin Smithy, Black Smithy and Plumbing.

A Machine Shop is well equipped with various Machine Tools to meet the industry requirements. The laboratory gives an idea how to produce/Manufacture various components by using different Machines and tools which is widely used in the industries.

Technical drawing that is used to convey information about an object. The ability to read Drawing and Design is the most important requirement of all technical people in any profession. In Engineering Profession, it is very essential that the Engineers and Craftsmen are able to communicate their ideas and facts with each other clearly and without ambiguity. For this, Indus University provides a spacious Drawing Hall with latest drawing tables and apparatus to the students where they can draw their technical drawings. Teachers to provides individual attention to each and every student during their drawing and drafting based subjects practical classes.

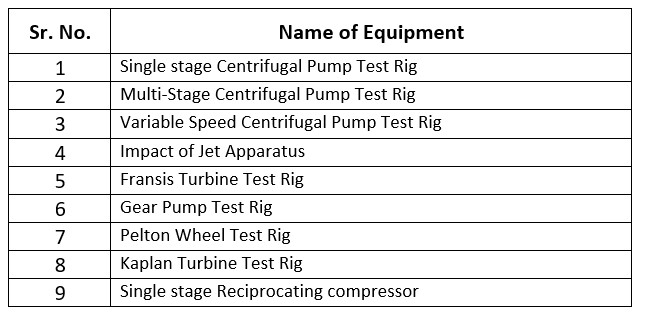

Fluid power is a term which was created to include the generation, control, and application of smooth, effective power of pumped or compressed fluids (water, oil, any other liquid or gases) when this power is used to provide force and motion to mechanisms. This force and motion maybe in the form of pushing, pulling, rotating, regulating, or driving. Fluid power includes hydraulics, which involves liquids, and pneumatic, which involves gases. Liquids and gases are similar in many respects. The main advantage of fluid power is that by less efforts we can get maximum output by using different hydraulic devices such as hydraulic jack, hydraulic lift, hydraulic crane, hydraulic press etc. In big, medium and small manufacturing industries this type of hydraulic systems are used at large scale to increase the efficiency of work. Power sectors in all over world different hydraulic turbines and pumps are playing key role to produce electricity.

This Fluid Power Engineering Laboratory gives hands-on practical exposure of fluid power and hydraulics of machines which includes impulse turbine and two types of reaction turbines i.e. Kaplan Turbine and Francis Turbine. Moreover this turbine setup is used to understand working and find efficiency of the turbine by practical readings. Additionally this laboratory has different types of centrifugal pumps for instance single stage, double stage and variable speed, and Gear pump setup which enable students to understand the construction and working of different types of centrifugal pumps and calculate efficiency and losses by practical performances. Practical setup of impact of jet gives basic idea and behavior of jet on different types of stationary and moving plates. All laboratory equipments are equipped with require storage tank and well mannered drainage system.