Announcement

Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!...Read more Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!

We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University....Read more We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University.

26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023....Read more 26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023.

Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!...Read more Get Ready for INDUS CUP 2K26! | Dates: 5–10 January 2026 | Stand a Chance to Win Cash Prizes up to ₹10,00,000!

We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University....Read more We are excited to announce the Indus Hackathon 2025, an exhilarating one-day event organized by the CSE Department of Indus University.

26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023....Read more 26th ISTE Faculty Annual State Convention will be held at Indus University on April 27, 2023.

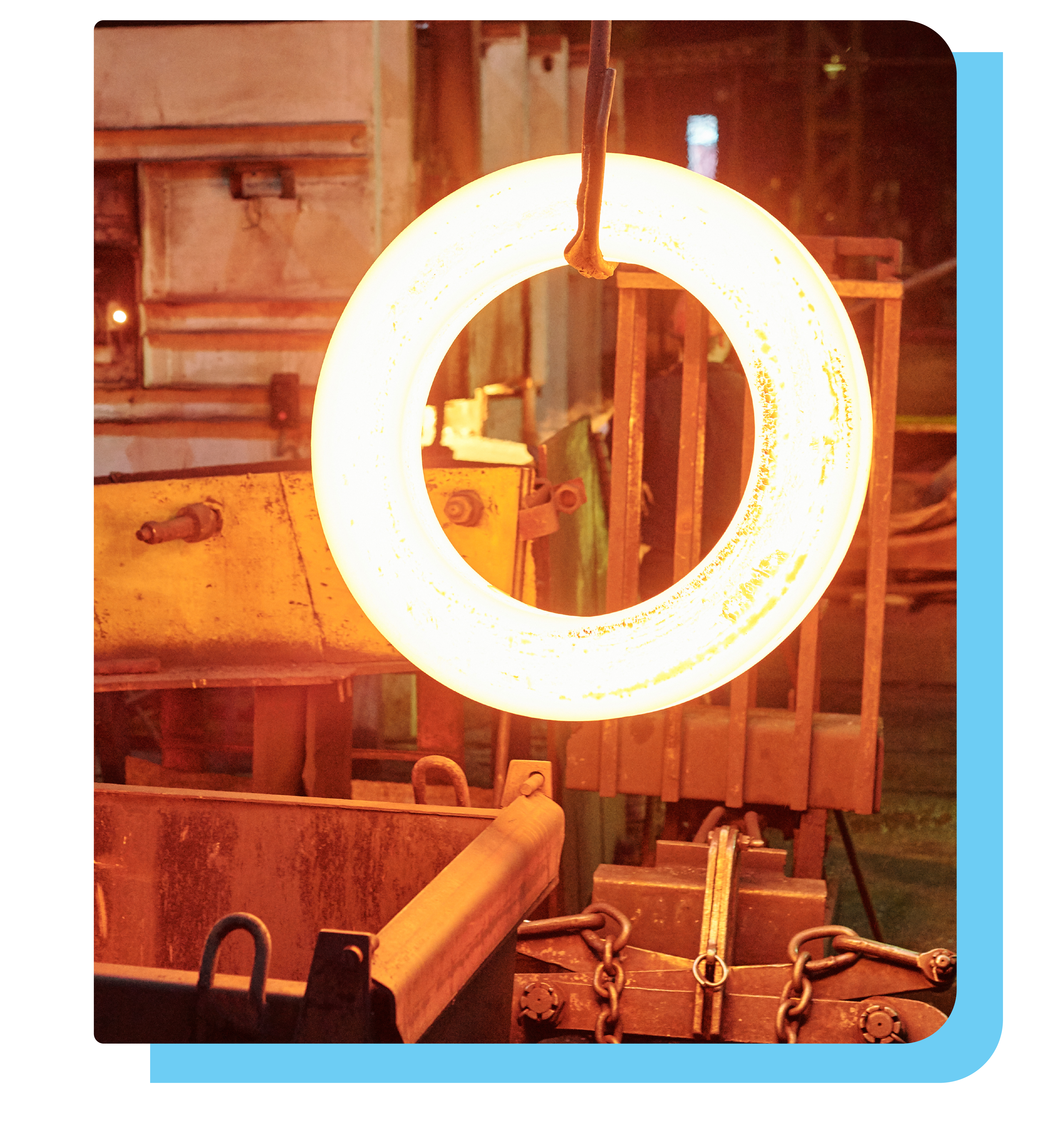

The foundry laboratory is equipped with various foundry sand testing equipment. Hands-on practice on foundry technology is provided through "Indus Foundry Training and Research Centre" (IFTARC). The Welding Laboratory is housed with Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding machine for conducting experiments on metal joining processes. The student gains the knowledge and skill on various testing related to sand casting, casting process and welding.

|

Sr. No. |

Name of the equipment |

|

1 |

Rapid moisture meter |

|

2 |

Shatter index tester |

|

3 |

Sand washer ( clay washer ) |

|

4 |

Permeability meter |

|

5 |

Send mixture ( Muller ) |

|

6 |

Universal strength machine |

|

7 |

Core hardness tester |

|

8 |

Sand rammer |

|

9 |

Mould hardness tester |

|

10 |

Digital balance |

|

11 |

Hot shell tensile tester |

|

12 |

Wet tensile tester |

|

13 |

Core gas determination |

|

14 |

Induction furnace |

|

15 |

Universal sand testing equipment |

|

16 |

Resistance furnace |

|

17 |

TIG welding set up |

|

18 |

MIG welding set up |

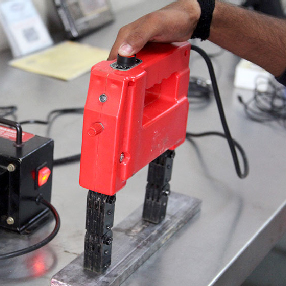

This Laboratory is equipped with basic Non–Destructive Testing (NDT) equipment for testing and perform the corrosion related experiments. Students carry out experiments to evaluate the corrosion resistance of various materials. Corrosion experiments are performed as per various standards such as ASTM B117, ASTM D2688, ASTM G67, ASTM 262, ASTM G31 etc. The lab is equipped with equipment needed for NDT such as Ultrasonic testing device, Magnetic particle inspection kit, Liquid Penetrant Test kit which are used to perform testing of components without destroying them and help them in assessing reliability.

|

Sr. No. |

Name of the equipment |

|

1 |

Single pan Balance (keroy) |

|

2 |

Magnetic stirrer |

|

3 |

Hot plate 8" round |

|

4 |

Ultrasonic flaw detector |

|

5 |

Magnifying glass with UV light |

|

6 |

Digital pH meter |

|

7 |

Magnetic particle testing kit |

|

8 |

Liquid penetrant inspection kit |

|

9 |

Salt spray tester |

Microstructural study of various metals and alloys, including the determination of volume fractions of phases and their distribution, are carried out by UG and PG students using microscopes and image analysis system. The lab is also equipped with heat treating furnaces that can run in controlled atmosphere. Students are able to understand the structure-property correlation of metals and alloys.

|

Sr. No. |

Name of the equipment |

|

1 |

Dry belt surfacer |

|

2 |

Optical microscopes |

|

3 |

Polishing machine (double disc) |

|

4 |

Muffle furnace |

|

5 |

Specimen mounting press |

|

6 |

Jominy end quench apparatus |

|

7 |

Hand polishing stainless steel stand |

|

8 |

Reduction furnace |

|

9 |

Optical pyrometer |

|

10 |

Microscope with image analyzer |

|

11 |

Thermocouple calibration test rig |

|

12 |

Micro hardness tester |

|

13 |

Bomb calorimeter |

|

14 |

Brinell hardness tester |

|

15 |

Rockwell hardness tester |

|

16 |

Universal testing machine (40 ton) |

Mineral dressing and mineral processing are two crucial components in process metallurgy. Its laboratory is equipped with machine for performing experiments for mineral dressing and mineral processing. It helps students to understand various beneficiation processes used for refining ores.

|

Sr. No. |

Name of the equipment |

|

1 |

Sieve shaker gyratory with sieves |

|

2 |

Jaw crusher |

|

3 |

Roll crusher |

|

4 |

Ball mill |

|

5 |

Froth floatation unit |

|

6 |

Abrasive cut off machine |

|

7 |

Hot Air Oven (Temp. Rang : 350c) |

|

8 |

Reduction furnace |

|

9 |

Compression testing machine |

|

10 |

Holder for holding the elements |

|

11 |

Disc pelletizer |

|

12 |

Sintering furnace for powder metallurgy |