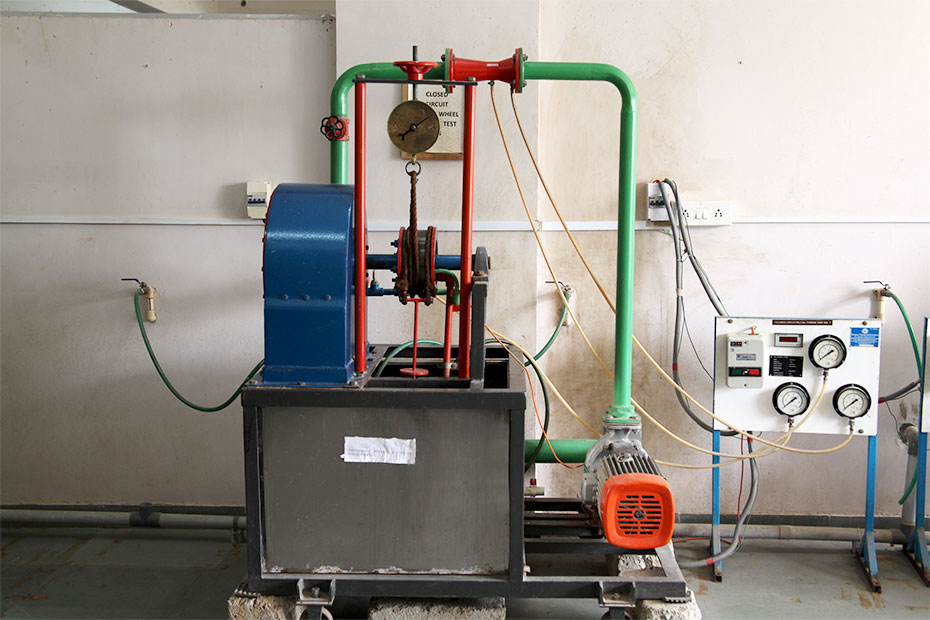

Mechanical Workshop

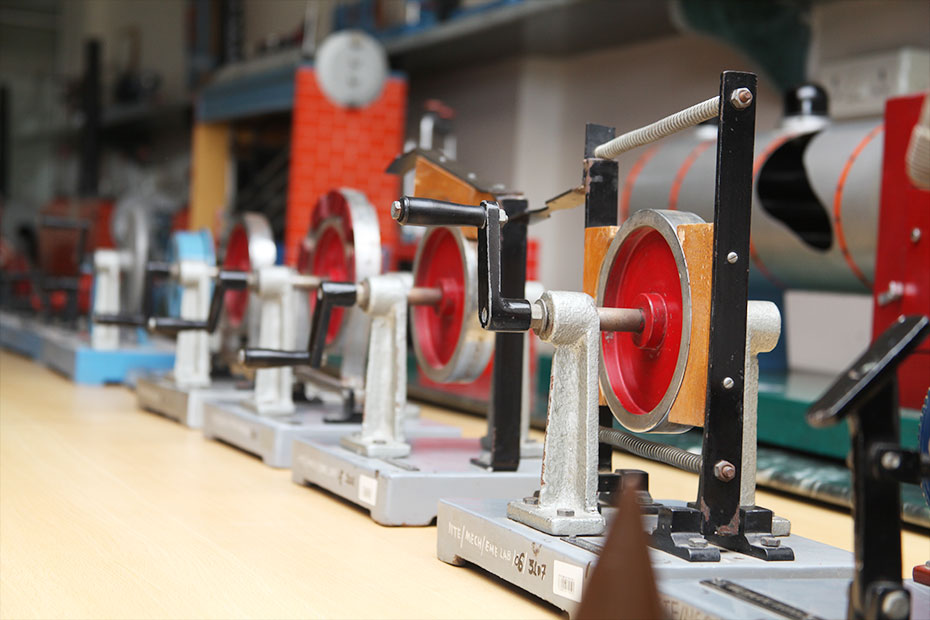

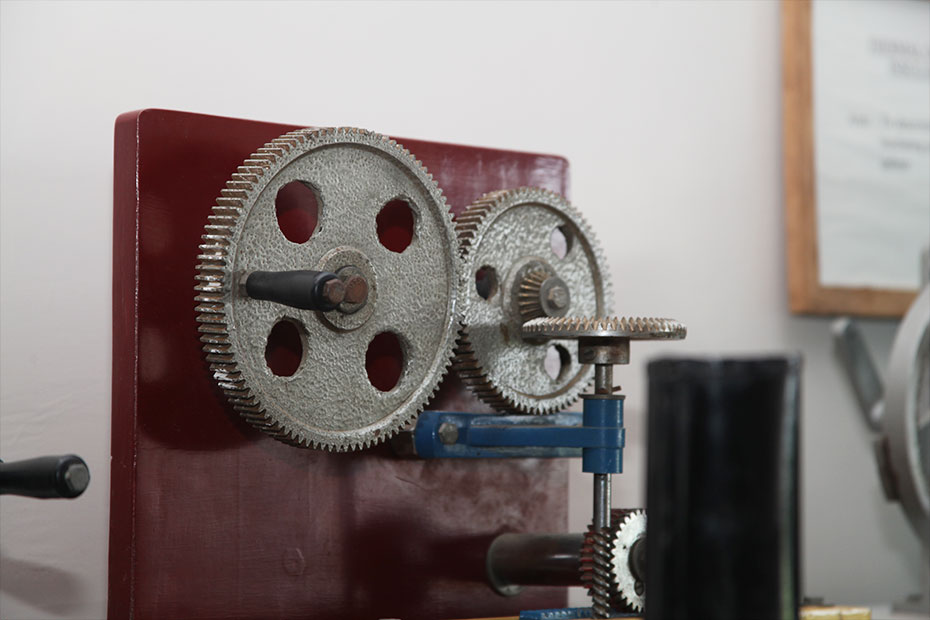

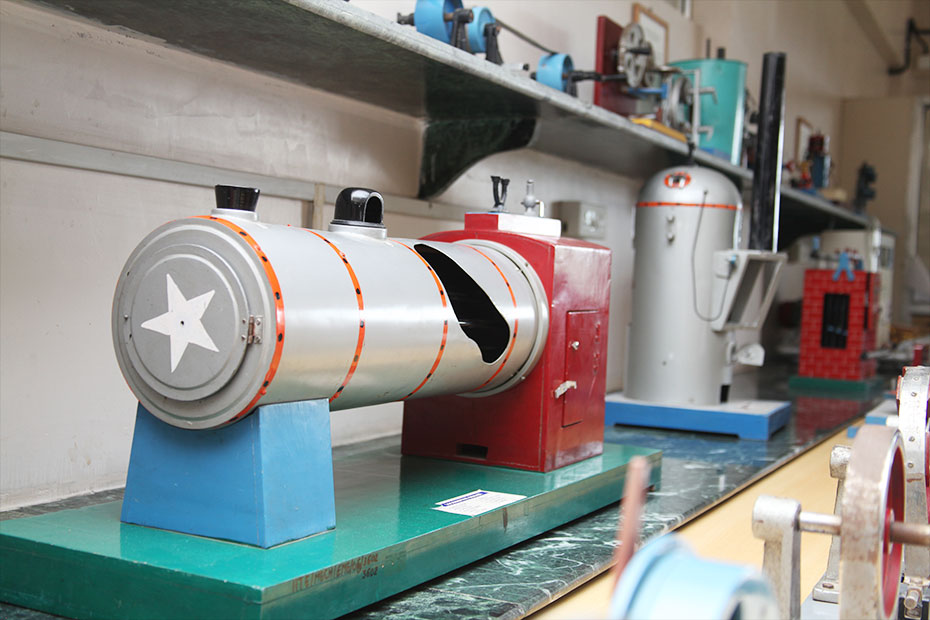

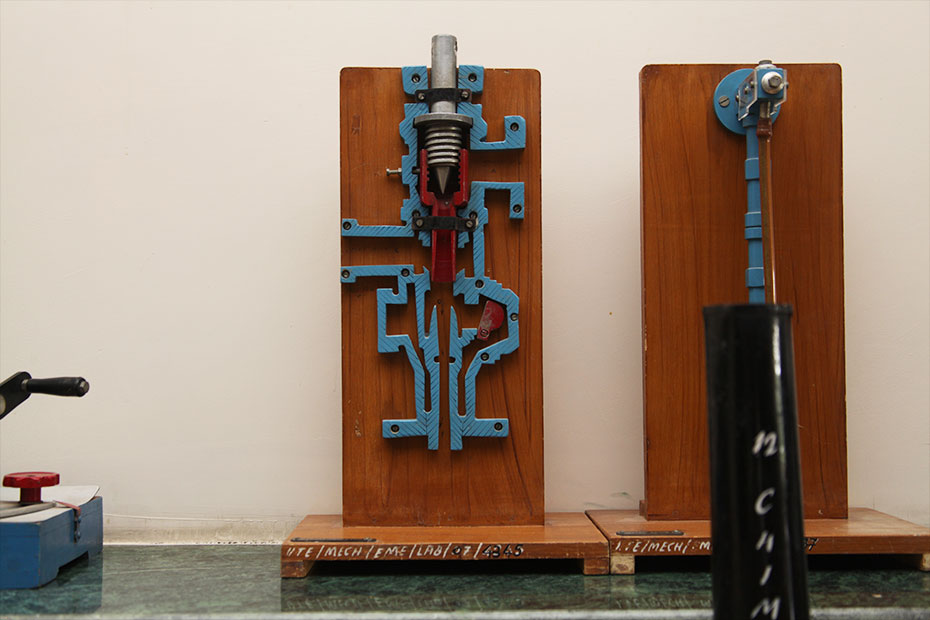

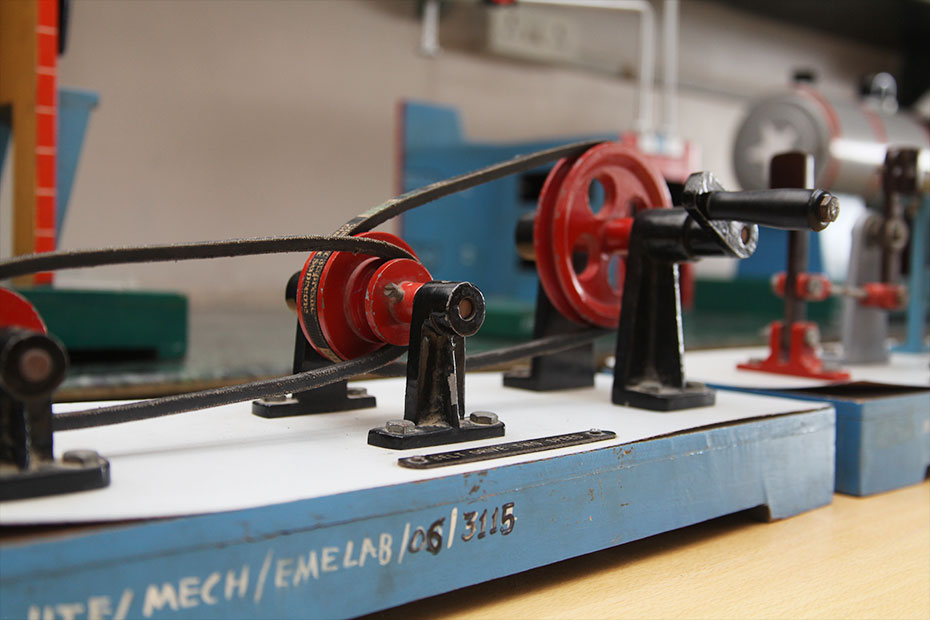

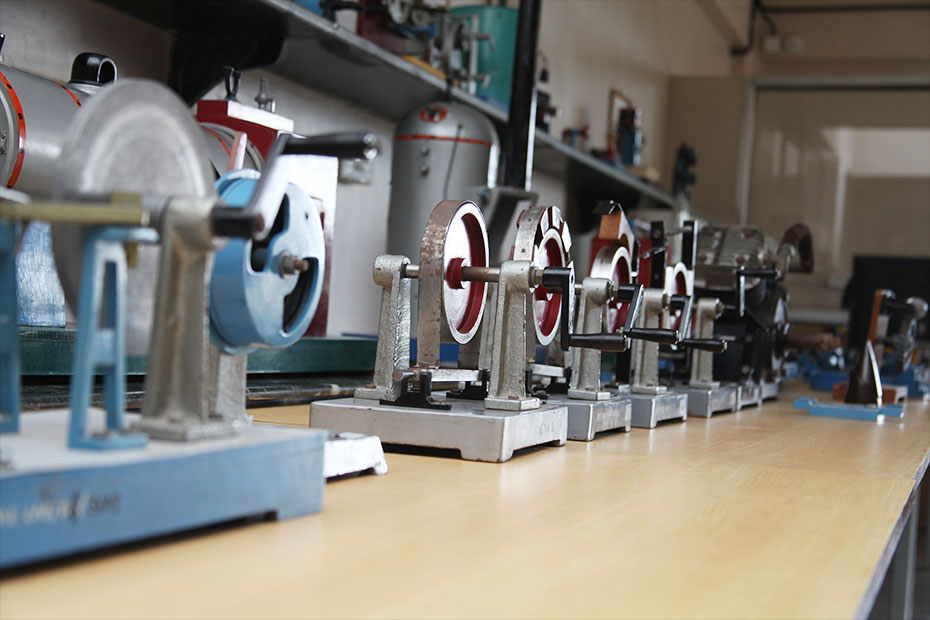

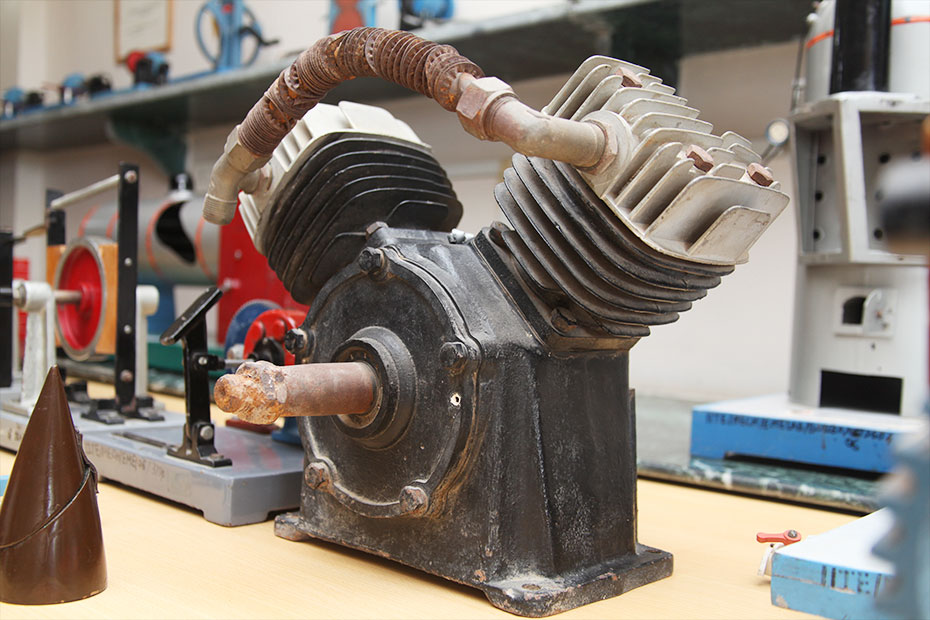

Mechanical Engineering is the discipline that applies engineering, physics and materials science principles to design, analyze, manufacture, and maintain mechanical systems. The mechanical engineering field requires an understanding of various methods and processes by means of which one can convert the idea into physical products. To achieve the basic objective and to bridge the gap between Theory and Practice, a Department of Mechanical Engineering is equipped with various Machines, Tools and Equipments in Mechanical Workshop.

The Mechanical Workshop is divided into two groups as follows;

1. Basic Workshop Practice

2. Machine Shop

Basic Workshop activities are helpful for molding the skill and quality of the students to design and fabricate something by hand. The laboratory work is having hand’s on practice by using various tools and Equipments on different materials like; Wood, Metal, pipes etc. The basic workshop contains 6 different shops like; Fitting, Carpentry, Tin Smithy, Black Smithy and Plumbing.

Major Equipments:

- Fitting Vice

- Carpentry Vice

- Plumbing Vice

- Bench drilling machine

- Wooden hacksaw machine

- Power Hacksaw machine

- Arc Welding machine

- Spot Welding Machine

- Wood Finishing Machine

- Hand shearing machine (Sheet metal)

- Pipe Bending Machine